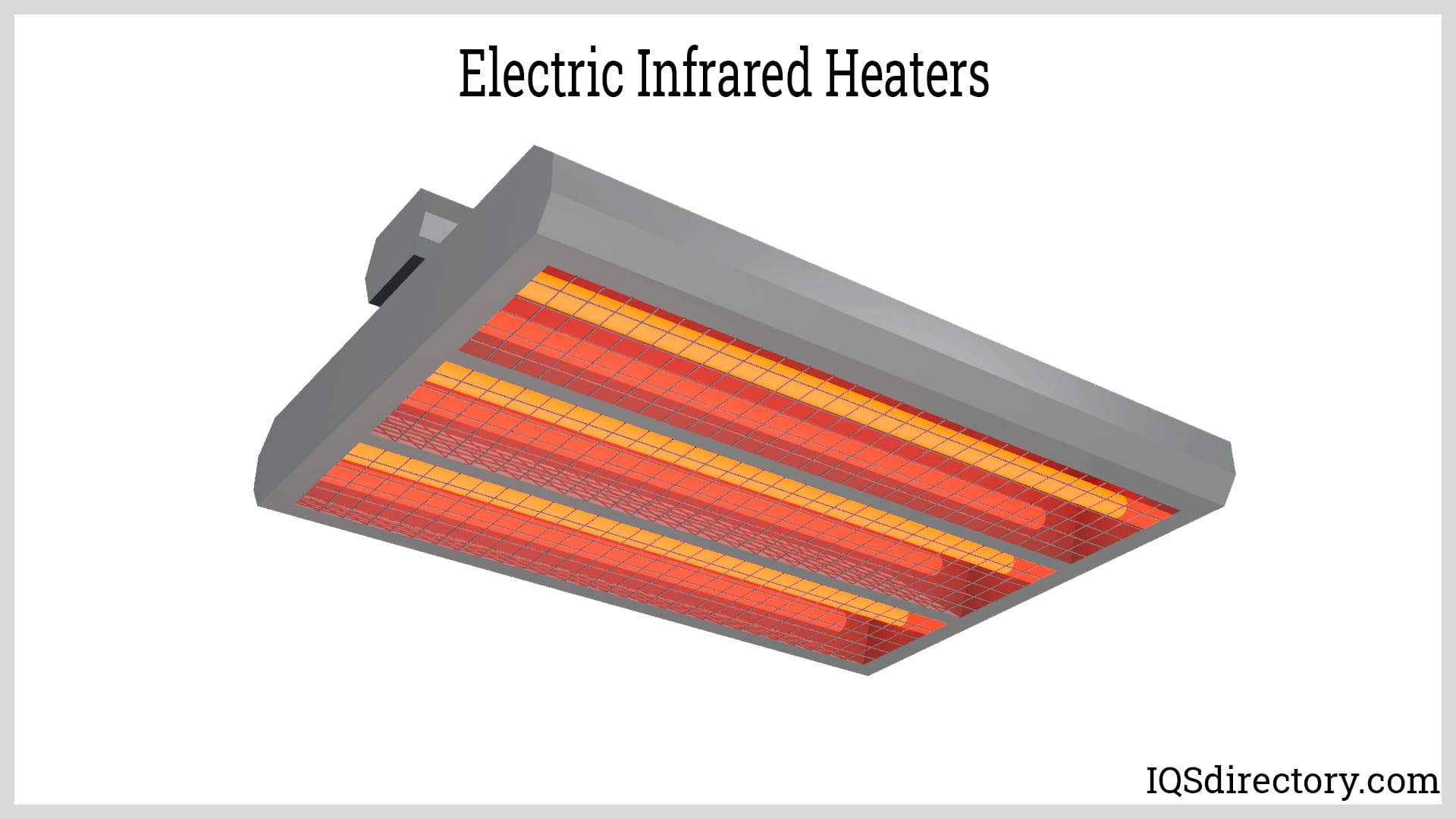

A heating technique called infrared heating uses infrared radiation to warm nearby individuals. Through electromagnetic waves in the infrared range, thermal energy is immediately transferred to a substance with a lower temperature. Infrared heaters are energy-efficient, practical, and healthy because the surrounding environment is not heated and is not involved in transferring heat. Electric infrared heaters efficiently and cheaply produce heat using electricity, natural gas, or propane. Read More…

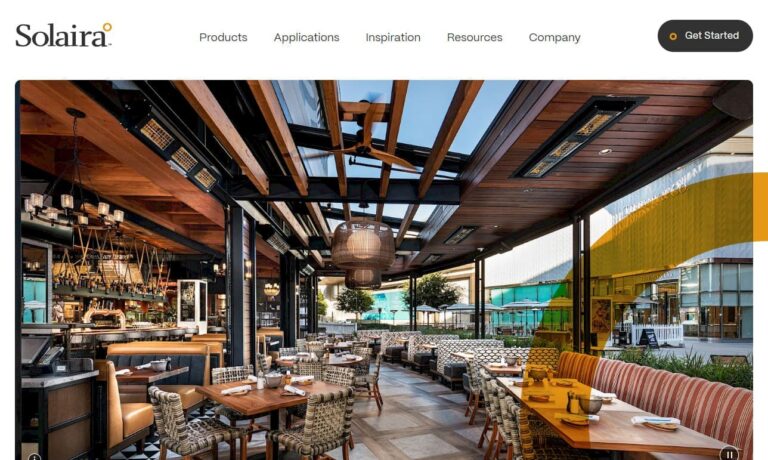

Economical, highly efficient, and satisfyingly effective Solaira™ quartz electric infrared heaters offer residential and commercial solutions that are second to none. We utilize the most up-to-date PHILIPS tm HeLeN quartz infrared technology to provide instant and directional radiant heat that is equivalent to the comfort of the sun actually warming you up and not just the air around you.

Area controlled heat that is clean and fast describes our infrared heaters. We have infrared heaters for everyone’s needs to choose from. Choose from portable heaters, infrared forging heaters, outdoor heaters, radiant heaters, electric infrared heaters and more. Our heaters are seen everywhere!

Mor Electric Heating offers Salamander electric ceramic infrared heating elements and panels, comfort spot heaters, pet and animal comfort heaters, portable comfort space heaters and industrial processing heaters. We can also custom design radiant heating panels for your needs.

Easy Radiant Works provides leading energy efficient infrared heating solutions. We offers a complete range of gas fired low and high intensity infrared heaters for industrial, commercial, sports facilities, hospitality, agricultural and residential applications throughout the United States. Our innovations continue to evolve; superior technology & performance remain constant. Contact us today to ...

More Electric Infrared Heater Manufacturers

For industrial processes, electromagnetic waves of wavelengths ranging from 780 nanometres to 10 microns can be used. In the infrared spectrum, shorter wavelengths correspond to higher frequencies and related energy. As a result, infrared rays can generate heat at temperatures up to 3,600° Fahrenheit.

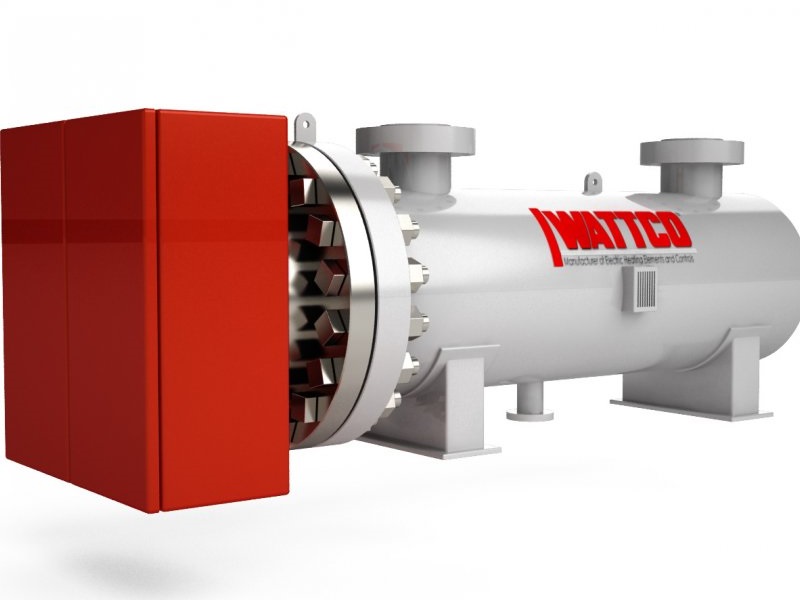

Today's electric infrared heaters come in various styles and functions to suit various industrial, commercial, and residential demands. They heat the surfaces in homes, workplaces, garages, and storage facilities. Infrared heaters are advantageous to industries because they can carry out a variety of processes, including drying, curing, and thermoforming. In addition, to improve rehabilitation, infrared heaters are utilized in medicine.

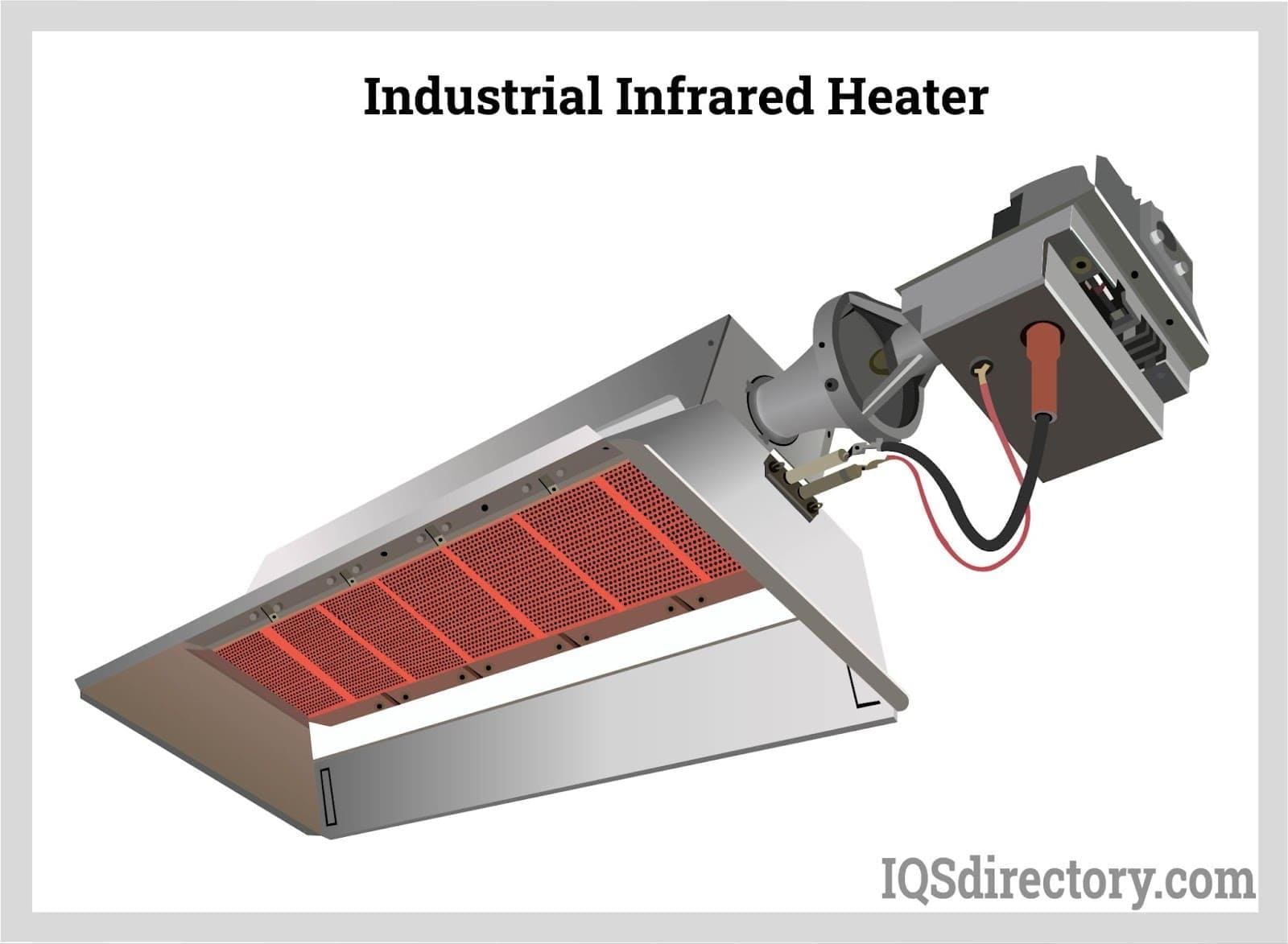

Working Principle of Infrared Heaters

A heating system and a reflector make up infrared heaters. The heating system produces thermal energy by converting electrical or chemical energy from fuel sources. The heating system's thermal energy is subsequently directed as radiant heat from the reflector to the nearby items.

Reflectors significantly influence the effectiveness of an infrared heater. To store less heat, they must be highly reflective and absorb little radiation from the heating system. Their forms and shapes are made to bend infrared radiation into space and stop them from reflecting. Reflectors also have the capacity to tolerate high temperatures throughout their service life, have a strong resistance to corrosion and moisture, and are simple to clean.

Aluminum, stainless steel, ceramics, and quartz are regularly used reflective materials. In addition, some reflectors have gold or ruby plating to improve reflection and concentrate more heat on the items around them.

Applications of Electric Infrared Heaters

Industrial uses for infrared heaters include drying paint and molding polymers. Commercial heating uses include those in construction, warehouses, and airplane hangars. Patio heaters, portable space warmers, convection ovens, incubator heat lamps, and dry saunas are a few examples of consumer usage.

Materials of Industrial Electric Infrared Heaters

Quartz, ceramic, and metal-sheathed infrared heaters are the three categories. They are electromagnetic infrared radiation heaters that quickly attain temperatures between 1,300 and 1,600° Fahrenheit for increased productivity and efficiency. The highest temperatures may be reached using quartz infrared heaters, whereas ceramic infrared heaters are the most cost-effective.

- Quartz Electric Infrared Heaters

The hottest form of infrared heat is produced by quartz infrared heaters, which have short wavelengths. Although they are not suitable for heating wide rooms, they are perfect for high-heat applications.

- Ceramic Electric Infrared Heaters

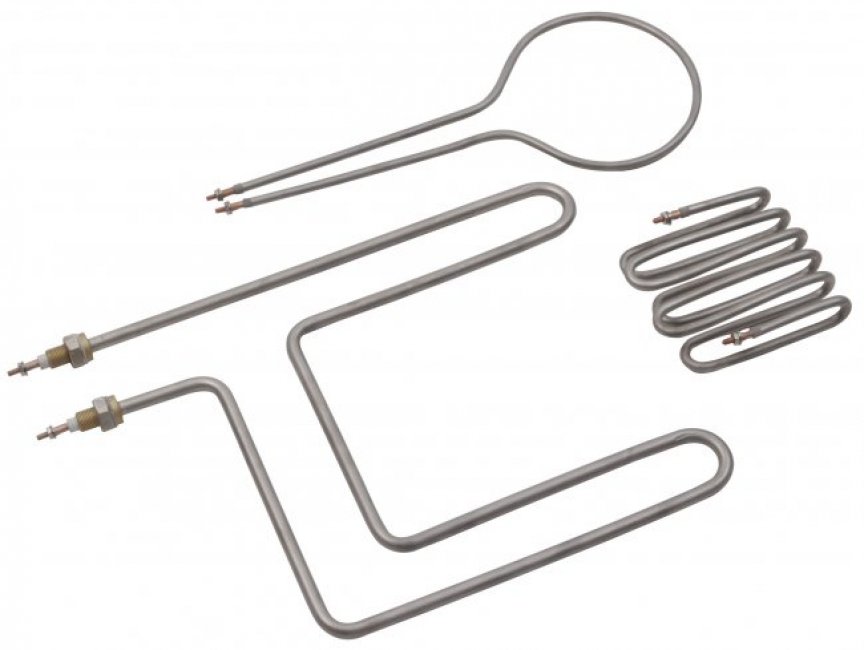

- Metal-Sheathed Electric Infrared Heaters

All three types of electric infrared heaters can achieve temperatures above 2,000o F, but metal-sheathed infrared heaters are the toughest. They can be utilized in applications requiring submersible heating.

Electric Infrared Heater Classifications

Electric infrared heaters include quartz lamps, quartz tubes, metal tubular, and ceramic emitters. However, these types' operating temperatures, wavelength, robustness, cost, and efficiency vary. The wavelength of the light that the element emits is used to classify different types of infrared heaters. Long-wave infrared heaters are frequently used in domestic settings, whereas short-wave infrared heaters may achieve high temperatures ideal for industrial procedures. When the wavelength of an infrared heater closely matches the absorption spectra of the thing being heated, its efficiency is at its best.

Benefits of Electric Infrared Heaters

Electric Infrared Heaters are Energy-Efficient

Electric Infrared heaters provide direct object warming. Since they don't utilize energy to heat the surrounding medium, heat losses are prevented. As a result, this feature lowers energy expenditures.

Electric Infrared Heaters Work Instantly

Instead of spending time heating the air and then transporting it to the objects, as is the case with conventional convection heaters, radiant heat is delivered to the nearby bodies—applications requiring drying benefit from this capability.

Electric Infrared Heaters give more Natural Heat

Electric Infrared heaters emit heat similar to radiant heat from the sun (excluding ultraviolet waves). However, they don't raise the humidity level, cut down on the oxygen in the air, or evaporate moisture from the air. As a result, we experience both warmth and revitalization when using infrared heaters.

Electric Infrared Heaters Reduce the Production of Molds and Mildew

Due to limited moisture mobility, electric infrared heaters prevent the growth of these microorganisms. This feature lessens nasal congestion, wheezing, and itchy skin and eyes. This environment is advantageous for handling, storing, and consuming food and medications.

Electric Infrared Heaters Operate Silently

Unlike convection heaters, most electric infrared heaters don't use fans or blowers to circulate the heated air. These supplementary devices produce noises that shouldn't be present in bedrooms and offices.

Electric Infrared Heaters are Environmentally-Friendly

Electric infrared heaters don't produce harmful fumes, gaseous waste, or airborne particles that are bad for the environment. In addition, they don't disturb the air in the vicinity, which contains allergies and dust. Infrared heaters' high energy efficiency also contributes to environmental sustainability.

Space heaters with low infrared temperatures lessen the possibility of unintentional house fires. Electric Infrared heaters can improve comfort by retaining the humidity that electric furnaces typically lose. Additionally, electric infrared heaters may aid households in avoiding dangerous pollutants like carbon monoxide and carcinogens typical of other fuels like heating oil.

Electrical Infrared Heaters have Amazing Health Benefits

- Electrical Infrared heaters make life better because they don't dry out the skin or the sinuses; infrared heaters are good for general health.

- They encourage blood flow.

- They support healthy respiratory function.

- They lessen inflammation and pain in the muscles and joints.

- They strengthen the body's defenses.

- They encourage restful sleep.

Choosing the Proper Electric Infrared Heater Supplier

To ensure you have the most beneficial outcome when purchasing an electric infrared heater from an electric infrared heater supplier, it is important to compare several companies using our directory of infrared electric heater suppliers. Each electric infrared heater supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each electric infrared heater business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple electric infrared heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services