Infrared heat waves are long electromagnetic waves located very near the visible part of the electromagnetic spectrum which can give off a large amount of heat that is easily absorbed by many surfaces when directed using a reflective shield. Read More…

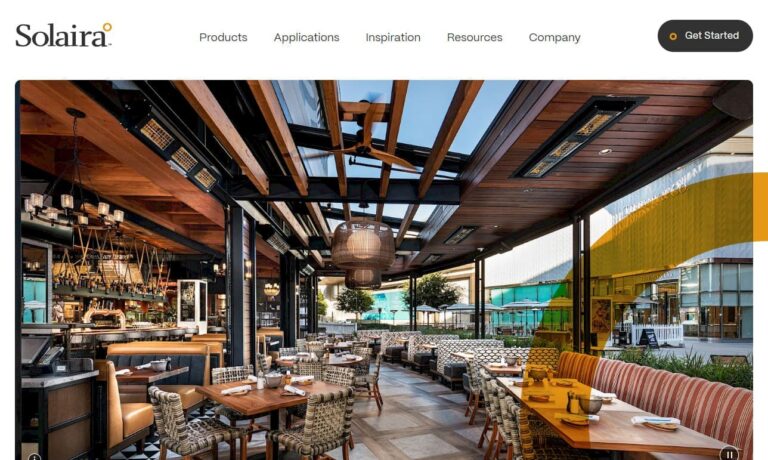

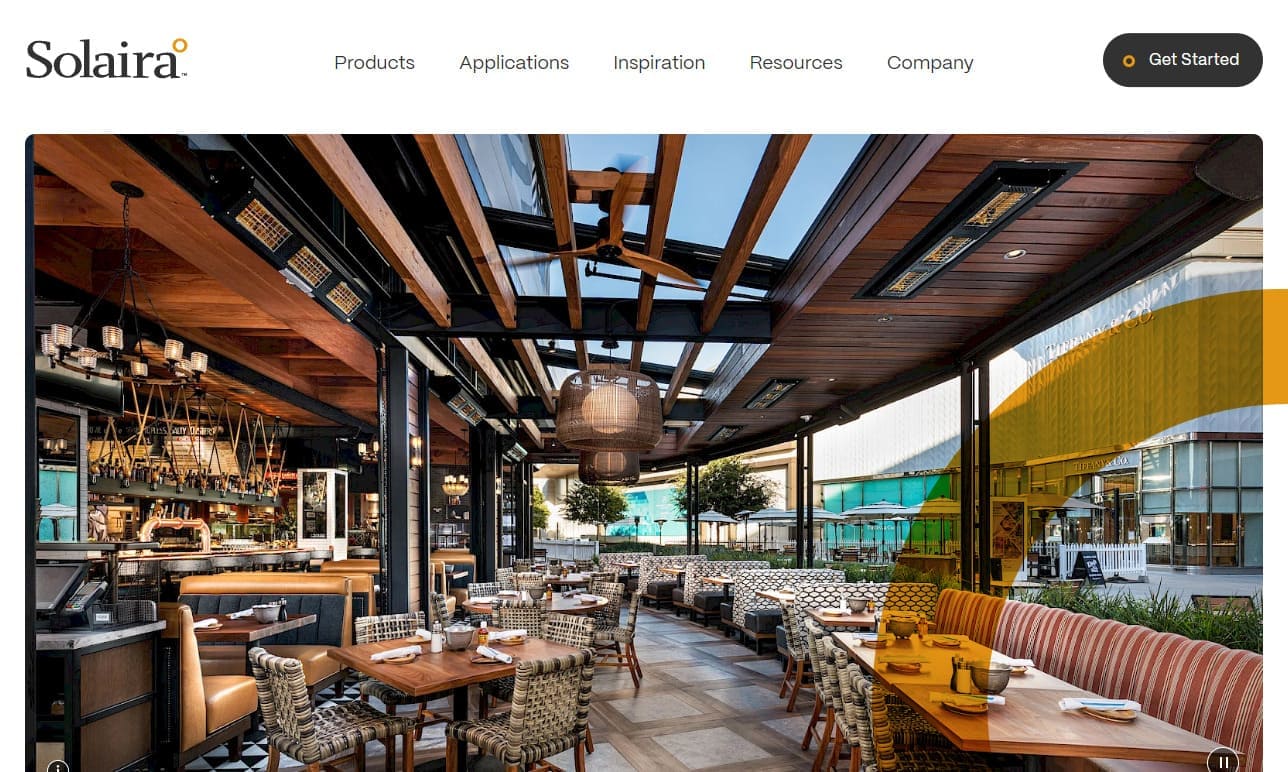

Economical, highly efficient, and satisfyingly effective Solaira™ quartz electric infrared heaters offer residential and commercial solutions that are second to none. We utilize the most up-to-date PHILIPS tm HeLeN quartz infrared technology to provide instant and directional radiant heat that is equivalent to the comfort of the sun actually warming you up and not just the air around you.

Area controlled heat that is clean and fast describes our infrared heaters. We have infrared heaters for everyone’s needs to choose from. Choose from portable heaters, infrared forging heaters, outdoor heaters, radiant heaters, electric infrared heaters and more. Our heaters are seen everywhere!

Mor Electric Heating offers Salamander electric ceramic infrared heating elements and panels, comfort spot heaters, pet and animal comfort heaters, portable comfort space heaters and industrial processing heaters. We can also custom design radiant heating panels for your needs.

Easy Radiant Works provides leading energy efficient infrared heating solutions. We offers a complete range of gas fired low and high intensity infrared heaters for industrial, commercial, sports facilities, hospitality, agricultural and residential applications throughout the United States. Our innovations continue to evolve; superior technology & performance remain constant. Contact us today to ...

More Radiant Gas Heater Manufacturers

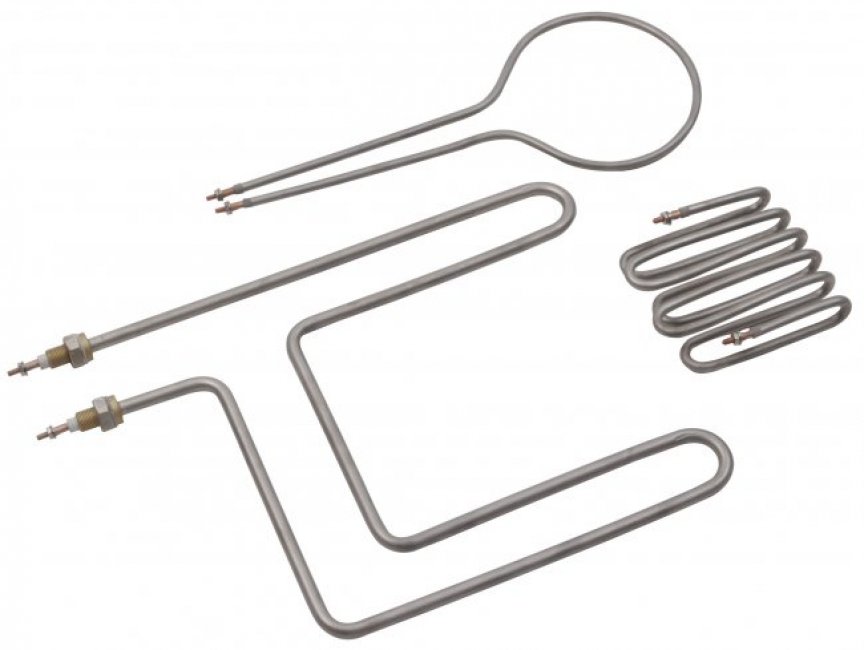

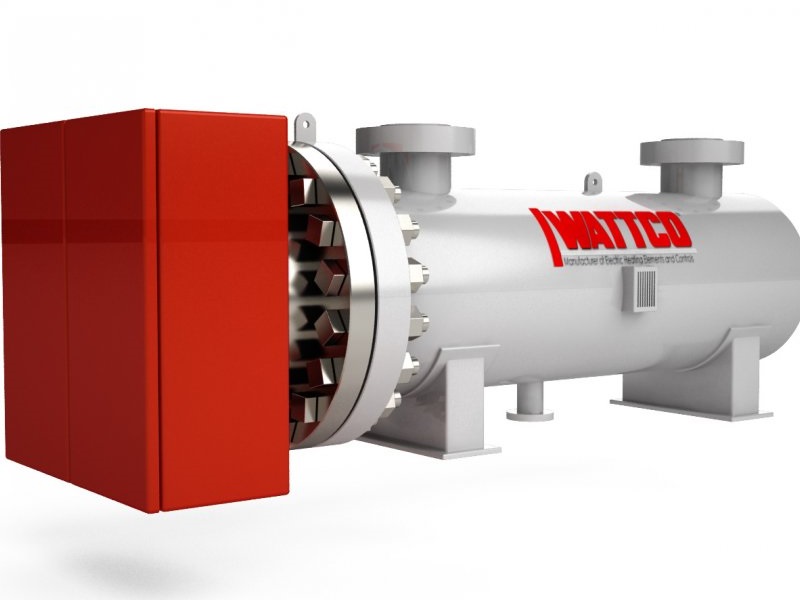

Produced by a natural gas flame, the infrared waves in radiant heaters give off radiant heat which is then absorbed by objects and surfaces without needing a medium or air molecules for transportation. Therefore, infrared heat can penetrate materials and gases more easily than typical convection heaters, and more efficiently than UV lamps which require light waves to effectively heat an object. Gas heaters use the heat energy from a gas flame and convert it into infrared electromagnetic radiation through filaments, tubes, or ceramic heat exchangers combined with a series of reflectors to direct the resulting heat.

The heating element is contained within a radiating tube typically made from glass, ceramic or metal. Due to this, gas heaters are sometimes referred to as tube heaters. Some radiant gas heaters may combine fans and air movement to redistribute heated air molecules and spread heat around a room faster, and other models may include a temperature detector, cooling options to allow for cryogenic use, weatherproof capabilities such as corrosion resistance materials etc.

Unlike other methods of heating, infrared light causes an immediate source of heat and removes the existence of a lag between turning the heater on and feeling its effects. It is especially useful in processes such as outdoor heating due to its ability to heat objects and surfaces rather than simply air molecules. Due to their high level of energy efficiency, infrared heaters are considered a "green" or environmentally sustainable method of creating heat. Using radiant gas heating in the place of regular forced air heaters in heating, drying and curing applications has a large number of benefits, both environmentally and economically.

Common uses for radiant gas heating include: room or space heaters, industrial uses such as plastic welding, curing, and drying of coatings or in glass processing. Further advantages to using infrared heaters include: the overall heat of the element being lower in infrared heaters results in a decreased risk of fire or burning. Furthermore, as infrared heaters do not rely on air molecules to transport heat and instead actually heat the object, or the air, heating patterns are more uniform throughout the space being heated, again using less energy and saving money.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services